Last news

VisiTouch 24 MX

VisiTouch 24 MXis a 3D graphical numerical control for CNC press brakes with a new solution

all-in-one:

Access Product Page- 24 inches surface Full Touch-screen and the CNC board mounted on the back of the screen.

- Full digital with CANopen® and EtherCAT® field buses controlling many axes

- Importing, programming, visualizing and simulating the bending of a part, all in 3D, quick,

easy and efficient. - Interface to all kind of hydraulic systems, I/O and analog axes thanks to

the CybMVA modules placed inside the cabinets.

VisiTouch CNC

VisiTouch CNC is an outstanding numerical control for multi-axes Machines Tools with a new solution

all-in-one:

Access Product Page- User friendly Multi-Touch interface.

- Open CNC platform allowing customization even for small quantities

- Multi-Channel

- 5-axis interpolation

- Easy to set up with our Wizard/Auto-tuning.

CybTouch 15PS Win

The CybTouch 15PS Win is a 2D numerical control specifically dedicated for mid-range CNC press brakes.

Access Product Page- Windows 10 for networking and remote maintenance.

- Unique experience with 2D graphic profile drawing (Touch Profile)

and 3D viewer thanks to a new quadcore processor unit. - Compatible with CANopen® and EtherCAT® fieldbuses for axes control.

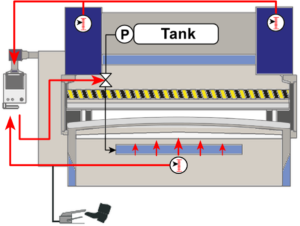

Collaborative Robots

Cobots can work almost anywhere and automate a wide range of tasks.

They allow operators to do what they do best: creating and working together.

Access Product PageThey allow operators to do what they do best: creating and working together.

- Small workshop can be already automated like larger factories.

- Complete range, payload from 3Kg to 20 Kg.

- One single CNC controlling both the press brake and the Cobot.

- No need to program the robot:

- The operator programs the part to be bent and then the robot

program is generated automatically. - The operator doesn’t have to worry about the robot at all, either

during programming or during production.

- The operator programs the part to be bent and then the robot

CybTouch 12 PS

CybTouch 12 G

VisiTouch PC Box